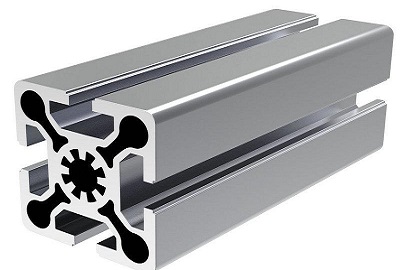

Aluminum extrusion is to put aluminum ingots into a container and apply a certain pressure to form various shapes through die holes. This container is a tool made of steel, also called a mold. During the extrusion process, the quality and size of the mold directly affect the quality of the profile. Because the mold is constantly worn under the harsh environment of high temperature and high pressure, the mold The daily maintenance work is very important. This extruded aluminum material is extrusion aluminum profiles.

At present, the competition in the aluminum profile market is very fierce. Enterprises have tried every means to manage the use and maintenance of aluminum extrusion molds in order to minimize production costs. Because the cost of the mold accounts for 35% of the production cost of the extrusion of the profile, although the mold has a high heat resistance and wear resistance, due to the high friction frequency of the mold, the service life of many molds is very short, and the scrap rate is quite high. Aluminum profile manufacturers have caused great economic losses. In response to this phenomenon, how should we pay attention to the use and maintenance of extrusion aluminum profiles in daily production?

In order to extend the service life of aluminum extrusion dies, we must proceed from the following aspects:

1. Nitriding should be done before the mold is used, the purpose is to ensure the toughness of the mold, improve the hardness, and wear resistance. Mold needs to be subjected to 3-4 nitriding treatments in its lifetime, not more than 5 times. Otherwise, it will easily cause the delamination of the working belt. The specific operations are as follows: the first die is nitrided after passing the inspection; the second nitridation is performed after extruding 5-10 aluminum bars; After the third nitridation, 100-120 aluminum rods can be extruded, and the thickness of the nitrided layer should reach 0.15mm each time.

2. Before the mold is put on the machine, the work belt should be polished. The quality of the nitriding in the front will affect the smoothness of the work belt polishing. Blow the dust and debris in the mold cavity with an air gun, or clean it with a brush to prevent the aluminum alloy from scratching the work belt when flowing, resulting in scratches on the surface of the aluminum profile.

3. Pay attention to the correct method of cooking the mold, and do not immediately put the mold into alkaline water for washing. Because the temperature of the mold is as high as 500°C at this time, it is much higher than the temperature of the alkaline water. Immediately put in the alkaline water can quickly cool down, but it can also cause the mold to crack. The temperature of the mold should be naturally reduced to 150 after the mold is unloaded. °C and then put into alkaline water to wash.

4. The heat preservation time of the mold is in the range of 2-3h, and cannot exceed 8h. If the time is too long, the hardness of the nitride layer of the mold will be reduced, resulting in a rough appearance or scratched surface of the aluminum profile.

5. Strictly control the alloy composition of the aluminum ingot and optimize the extrusion process. When the mold is just put into use, because the internal structure is still unstable, the use intensity should not be too high. It must first transition from low to high for a period of time, and then reduce the intensity from high to low to extend the service life of the mold.

6. According to the cross-sectional shape and complexity of the aluminum profile, choose an appropriate tonnage extruder. When selecting, it is necessary to calculate the tonnage of the extruder according to the wall thickness and extrusion coefficient of the profile. The cross-sectional shape of many profiles is very complicated, which causes great difficulties in the design of the mold. If it is not planned in advance, it will increase a lot. Unnecessary workload may even cause economic losses to the enterprise.

7. From the time when the mold is accepted and put into use until it is scrapped, various records must be made, a corresponding file should be established for each set of mold, the service life of each mold is different, and the various uses and records of the mold during service are recorded The maintenance situation also reflects the production of aluminum profiles from the side.

8. After using the mold, clean the inside and outside of the mold cavity, remove oil and dust, and attach a label for recording and storage for the next use.