Aluminum extrusion molding is to apply strong pressure to the metal blank placed in the mold cavity to force the directional plastic deformation of the metal blank and extrude from the die hole of the extrusion die to obtain the desired cross-sectional shape, size and have Plastic processing method of mechanical properties of parts or semi-finished products. Building materials extrusion aluminum profiles is a commonly used extruded aluminum material.

According to the direction of metal plastic flow, extrusion can be divided into the following categories:

Positive extrusion: during production, the metal flow direction is the same as the punch movement direction

Reverse extrusion: during production, the metal flow direction is opposite to the moving direction of the punch

Compound extrusion: during production, part of the billet metal flow direction is the same as the punch movement direction, and the other part metal flow direction is opposite to the punch movement direction

Radial extrusion: during production, the metal flow direction is 90 degrees to the moving direction of the punch.

1. During the extrusion process, the extruded metal can obtain a stronger and more uniform three-dimensional compressive stress state than the rolling and forging in the deformation zone, which can give full play to the plasticity of the processed metal itself.

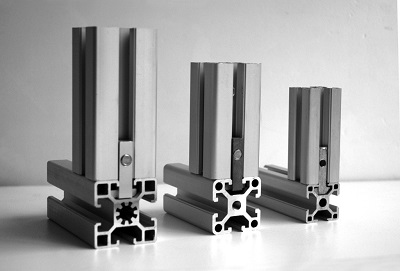

2. Extrusion molding can not only produce rods, tubes, shapes, and wire products with simple cross-sectional shapes but also produce profiles and pipes with complex cross-sectional shapes.

3. Extrusion has great flexibility, and only need to change the extrusion tools such as molds, you can produce products with different shapes and varieties on one device. The operation of replacing the extrusion mold is simple, fast, time-saving, and efficient.

4. The precision of extruded products is high, the surface quality of the products is good, and the utilization rate and finished product rate of metal materials are also improved.

5. The extrusion process has a good influence on the mechanical properties of the metal.

6. Short process flow, convenient production, one-time extrusion can obtain a whole structural part with a larger area than hot die forging or forming rolling, etc., less equipment investment, low mold cost, high economic benefit.

7. Aluminum alloy has good extrusion characteristics, especially suitable for extrusion processing, and can be processed by various extrusion processes and various mold structures.

In recent years, due to the pursuit of miniaturization and weight reduction in various industries, aluminum, and aluminum alloy profiles have been widely used in construction, transportation, electronic appliances, aerospace, and other industries. Therefore, the proportion of aluminum extrusion products has also increased rapidly. According to the data, aluminum and aluminum alloy products account for more than 70% of the extrusion products. In the future, support custom building materials extrusion aluminum profiles will be used more and more widely.