Rail transportation aluminum alloy: Rail transportation mainly includes: railway passenger transport, freight train, subway, light rail and maglev train, etc. Our products are mainly used in high-speed railways and subways. Lightweight rail transportation. In particular, the central issue of the modernization of lightweight rail transportation for high-speed railways and subways, and a large amount of aluminum alloy materials is the most effective way to increase the weight of vehicles. Therefore, it has higher requirements on the strength and toughness of aluminum alloy for rail transportation. France was the first to use aluminum alloy materials in the window frames of rail transport passenger cars; the United Kingdom also used aluminum alloys to make the outer wall panels and interior decoration materials of trams in 1905; between 1923 and 1932, the United States used aluminum alloys on rail vehicles Manufacture of doors and windows, roofs, outer wall panels, inner wall pipes, bogies, wheel cores and decorative materials for electric vehicles and passenger cars, etc. In the following decades, aluminum alloys were widely used in the production of rail vehicles in various countries around the world, from the initial manufacturing of some vehicle components with aluminum alloys to the development of all-aluminum structural vehicles in which the basic structural components of the vehicles were all made of aluminum alloys.

First of all, the density of aluminum alloy is only one-third of that of steel. Under the same conditions, compared with the copper-containing wear-resistant steel car body structure, the quality of the stainless steel car body can be reduced by about 15%, and the mass of the aluminum alloy car body can be reduced by more than 35%. Due to the reduced weight, the aluminum alloy car body can be increased Transportation volume is 10%.

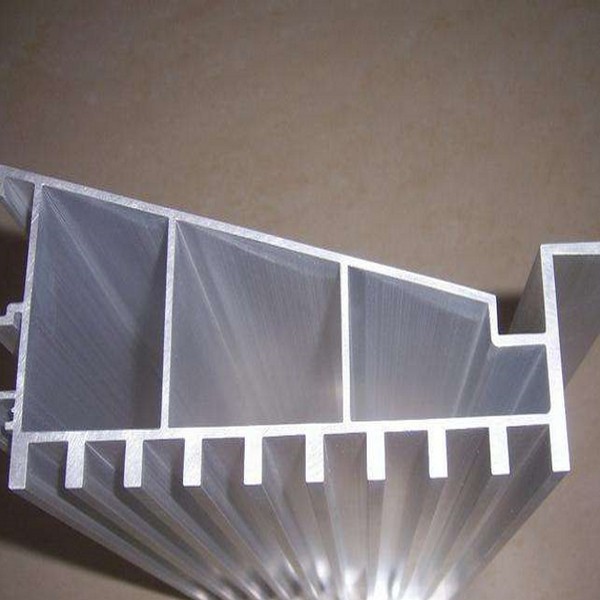

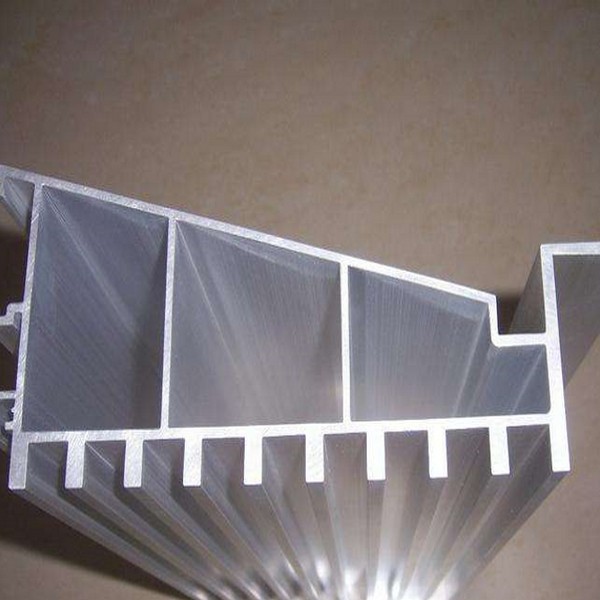

Secondly, although the fatigue resistance and impact resistance of aluminum alloys are not as good as steel, with the development of technology, many high-performance aluminum alloys have been successfully developed and aluminum alloy monolithic hollow wall panels have been successfully developed. It can completely solve the defects of appealing aluminum alloy.

Finally, the aluminum alloy has better fire resistance, arc resistance, and heat dissipation than steel; also, a thin oxide protective film can be naturally produced on the surface of the aluminum alloy. It has better corrosion resistance than steel.

No specific size, according to the size requirements in your drawings, we support product customization.

Rail transit, subway, railway passenger car, freight train, subway, high-speed railway, etc.

Delivery time of goods: 15-35 days

Mold delivery time: 7-15 days

Standard and later warranty

1. GB5237-2008 is equal to EN12020-1. 2 (2001);

2. No surface quality problems within ten years.