Woodgrain transfer profile means that based on powder spraying or electrophoretic painting, according to the principle of high-temperature sublimation heat penetration, the wood grain pattern on the transfer paper or transfer film is quickly transferred and penetrated by heating and pressure Onto profiles that have been sprayed or electrophoresed. The aluminum alloy doors and windows of the wood grain profile produced have a clear texture, strong three-dimensional sense, and can better reflect the natural feeling of the wood grain. It is an ideal energy-saving and environmentally friendly material to replace traditional wood.

Transfer the surface treatment of wood grain aluminum profile, transfer the flower warm pattern on the transfer film to the surface of aluminum powder coating to achieve the decorative effect of wood or stone It is wear-resistant and fire-resistant. It can maintain 15 years of color change when used outdoors. It also has excellent physical and chemical properties such as lightweight and high strength. It has clear and realistic patterns and has a fake and real visual effect. , Building materials and other industries is an emerging material surface treatment technology in the world.

The transfer equipment is used to decorate aluminum profiles, various metal plates and profiles to achieve the effect of wood products or marble. The heat transfer equipment is based on the principle of sublimation, which can be used in 3-5 minutes. The wood grain or marble pattern is quickly printed to the surface of the aluminum profile powder coating and can penetrate 40-60 microns inside the coating.

The production process of aluminum transfer is as follows

1. Use a film machine to cut the transfer film into the required size;

2. Transfer the cut transfer film;

3. On the packaging platform, insert the worker into the work bag made of transfer film;

4. Place the workpiece covered with the transfer film on the trolley platform of the heat transfer machine, and then put 18 aluminum materials in sequence. Connect the vacuum heads to both ends of the aluminum materials and tighten them. Turn on the vacuum switch. At this time, the transfer film is tight. Tightly attached to the aluminum material, the trolley automatically sends the aluminum material to the barbecue, the barbecue automatically heats 220 degrees and keeps warm for 3 minutes, the trolley automatically exits the barbecue;

5. Loosen the vacuum tap and remove the workpiece;

6. Remove the transfer film and check the quality of the workpiece.

The flat panel thermal transfer production process is as follows:

1. Use a film cutter to cut the thermal transfer paper roll to the required size;

2. Attach the heat transfer paper film to the surface of the workpiece and place it on the flat plate heat transfer machine;

3. Push the flat plate to the heating area of the flat thermal transfer machine, press the pressure plate switch, the pressure plate presses the thermal transfer paper tightly on the workpiece, heat and keep warm for one minute;

4. Raise the pressure plate, push the workpiece to the piece section, remove the transfer film, remove the workpiece and check it.

Woodgrain has strong adhesion to aluminum, non-toxic, no odor, easy to clean. The product has clear and vivid lines, strong three-dimensional sense, good appearance decoration effect, and has the visual effects of returning to the original and returning to nature. The coating film on the surface of the sprayed aluminum profile is non-volatile and non-oxidizing in the air, without any pollution to the environment. The dirt deposited on the sprayed surface can be restored to its original luster and appearance once it is cleaned.

We can process the size range: the maximum size of the square tube is 100 * 100mm, the maximum diameter of the round tube is 120mm, and the maximum diagonal length is 165mm.

length: ≤7m, Wall thickness: ≥0.8mm

Alloy composition and temperature, AL 6063, T4 / T5 / T6, or customized according to your needs.

Surface treatment technology: powder coating, wood grain, polishing, wire drawing, sandblasting, etc. can be achieved.

We can provide personalized customization services as follows:

1. Use our existing molds at no additional cost

2. Use your drawings to open the mold, to achieve a certain order quantity free of mold fees

3. When the order reaches a fixed quantity, the molding fee will be charged by return

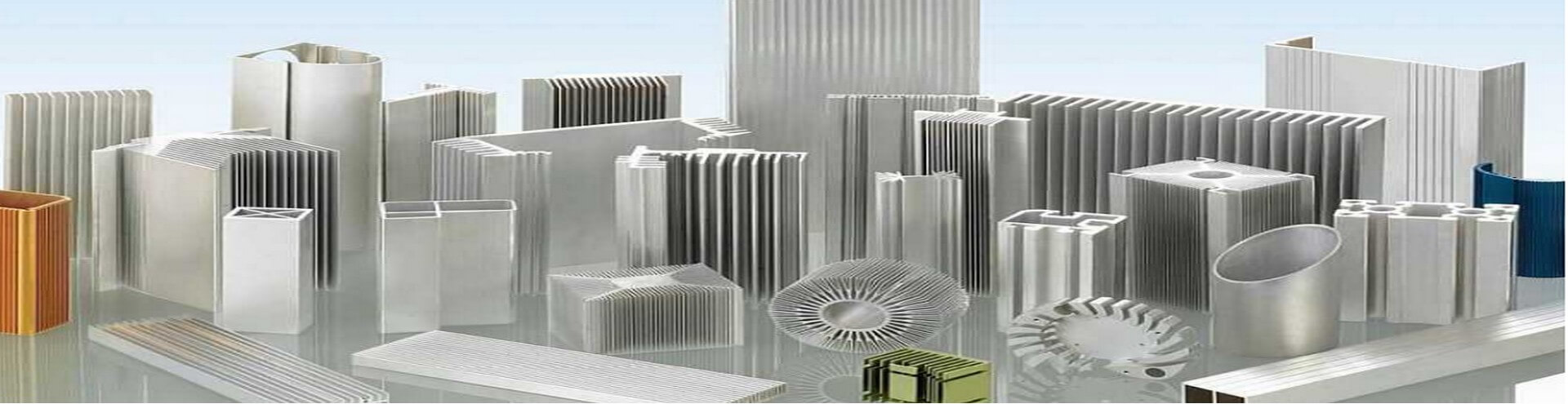

Can be used for windows, aluminum profile curtain walls, thermal insulation aluminum profiles, industrial aluminum profiles, radiators, solar frames, aluminum profiles for kitchen cabinets, aluminum profiles for wardrobes, aluminum profile railings, aluminum furniture, office partitions, Aluminum blinds, aluminum tile finishes, aluminum profiles for the sunroom, aluminum profiles for the shower room, etc.

Delivery time of goods: 15-35 days

Mold delivery time: 7-15 days

Standard and later warranty

1. GB5237-2008 is equal to EN12020-1. 2 (2001);

2. No surface quality problems within ten years